NPR OF AMERICA PRODUCTS

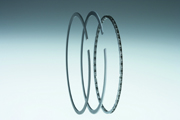

PISTON RINGS

For Gasoline Engine

For Diesel Engine

Piston rings maintain close contact with the cylinder walls through their own spring tension, carrying out such functions as sealing in combustion gases, carrying heat away from the pistons by thermal conduction, and controlling the thickness of the lubricating oil film on the cylinder wall. They must perform these functions under the severe conditions that occur in combustion chambers, while also playing the important roles of preventing seizure and minimizing wear on cylinder liners.

A piston ring must have both spring-like tension and the properties to become a true circle when closed. In the combustion chamber of engine, NPR’s piston rings serve to seal combustion gas, control lubricating oil, dissipate heat, and prevent wear and seizure under the severe conditions of operation. Now that engines are required to be more compact, lighter, and more sophisticated in performance, the choice of piston ring materials has been widened to include steel in addition to the traditional cast iron. Moreover, in order to enhance their wear resistance and durability, they also undergo various surface treatments including nitriding and PVD treatment.

PISTONS

For Gasoline Engine

For Diesel Engine

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings. In an engine, its purpose is to transfer force from expanding gas in the cylinder to the crankshaft via a piston rod and/or connecting rod. In a pump, the function is reversed and force is transferred from the crankshaft to the piston for the purpose of compressing or ejecting the fluid in the cylinder. In some engines, the piston also acts as a valve by covering and uncovering ports in the cylinder wall.

CYLINDER LINERS

Located within the cylinder block, the inside of the cylinder liner constitutes the combustion chamber of the engine. There are a variety of liners, including wet liners whose external circumference is directly exposed to cooling water, dry liners which are fitted into machined cylinder blocks, and aluminum cast-in liners whose inner periphery is machined after being cast into aluminum blocks. As with piston rings, the development of cylinder liners is now being pursued through liner-piston ring combination techniques in order to meet the CO2, NOX, PM, and other emission control standards as well as the requirement for higher fuel efficiency (reduction in weight).

VALVE SEAT INSERT

The “Valve seat insert”, which is press-fitted into valve seating face part with cylinder head, is made of sintered alloy. This is important parts, which require durability that there is no deterioration by hitting at high temperature and which require high gas tightness that combustion gas is sealed certainly. NPR has offered the superior valve seat insert which meets high level of requirements of engines, making use of abundant material variation and material development power.